Handmade Jiro Bessho Japanese Handsaws

Hishika's "Jiro Bessho" saws are forged, ground, filed, and finished by hand. As a result, every blade is significantly thinner and sharper than typical pull saws. The hand-ground taper reduces friction. These saws track straight, cut fast without binding, and leave a surface that needs little cleanup. These saws are precise, efficient, and can be maintained for a lifetime of work.

-

Jiro Bessho Ryoba - Precision Handmade Japanese Pull Saw

Regular price From $90.00 USDRegular priceUnit price per -

Jiro Bessho Azebiki - Handmade Japanese Pull Saw

Regular price From $60.00 USDRegular priceUnit price per -

Jiro Bessho Dozuki - Handmade Japanese Pull Saw

Regular price From $124.99 USDRegular priceUnit price per -

Jiro Bessho Hardwood Dozuki - Precision Handmade Japanese Pull Saw

Regular price $90.00 USDRegular priceUnit price per -

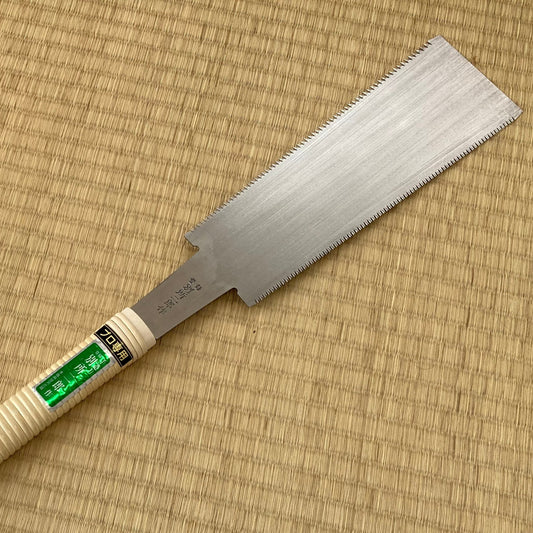

Jiro Bessho Pro Series Kataba - Precision Japanese Handsaw

Regular price $86.00 USDRegular priceUnit price per -

Jiro Bessho Hardwood Kataba - Precision Handmade Japanese Pull Saw

Regular price $80.00 USDRegular priceUnit price per -

Jiro Bessho Kataba - Precision Handmade Japanese Pull Saw

Regular price $82.00 USDRegular priceUnit price per

Juntaro Mitsukawa Japanese Handsaws

Juntaro Mitsukawa is one of the few remaining smiths in Japan still forging saws by hand. His blades are thicker than Bessho’s and treated differently. They are designed for strength and durability while still offering a clean, accurate cut. Mitsukawa’s work balances power with control, giving you a saw that feels solid in the cut and holds up under demanding use.

-

Juntaro Mitsukawa Hardwood Ryoba - Handmade Japanese Pull Saw

Regular price $110.00 USDRegular priceUnit price per -

Juntaro Mitsukawa Softwood Ryoba - Precision Handmade Japanese Pull Saw

Regular price $110.00 USDRegular priceUnit price per

Files & Saw Sharpening Supplies

A handmade saw will only perform at its best if it’s cared for. We stock the files necessary to keep our saws cutting true. These are not generic hardware store files, they’re sized to match Japanese saw tooth geometry and will sharpen the tool without damaging the steel.

-

Rare Tsubotama Smith-made Finishing Files

Regular price $30.00 USDRegular priceUnit price per -

Kakumatsu Feather Files - New Old Stock

Regular price $30.00 USDRegular priceUnit price per -

New Old Stock 150mm Feather Files

Regular price $30.00 USDRegular priceUnit price per